Market Summary

China Tool Holder Market Overview:

As per MRFR analysis, the China Tool Holder Market Size was estimated at 315 (USD Million) in 2024.The China Tool Holder Market Industry is expected to grow from 375(USD Million) in 2025 to 749 (USD Million) by 2035. The China Tool Holder Market CAGR (growth rate) is expected to be around 6.491% during the forecast period (2025 - 2035).

Key China Tool Holder Market Trends Highlighted

The China Tool Holder Market is experiencing notable growth driven primarily by the increasing demand from various manufacturing sectors. One of the key market drivers is the rapid industrialization in China, which is pushing for enhanced production efficiency and precision in manufacturing processes. The country is home to a vast number of manufacturing facilities, and as they modernize, the need for advanced tool holders that support automation and precision machining becomes critical. Additionally, the growing focus on smart manufacturing technologies, fueled by government initiatives to promote Industry 4.0, is encouraging manufacturers to invest in sophisticated tooling solutions.Recent trends in the China Tool Holder Market include a shift towards lightweight and high-strength materials to improve performance and durability. Manufacturers are also embracing innovation in design to enhance compatibility with a variety of machine tools, which is crucial given the diverse machinery used across different sectors in China. Moreover, environmental concerns are prompting a trend toward eco-friendly tool holder solutions as companies aim to reduce waste and increase sustainability in their operations. Opportunities in the China Tool Holder Market are expanding as local firms seek to enhance their international competitiveness.The government's support for small and medium enterprises (SMEs) in the manufacturing sector presents a chance for tool holder manufacturers to tap into new customer bases. Additionally, as the automotive and aerospace industries continue to flourish in China, there is significant potential for tool holders that cater to specialized applications within these sectors. Overall, the trends reflect a dynamic shift in the market as technologies evolve and industries transform in response to both domestic and global demands.

Source: Primary Research, Secondary Research, MRFR Database and Analyst Review

China Tool Holder Market Drivers

Growth in Manufacturing Sector

The China Tool Holder Market Industry is poised for significant growth driven by the expansion of the manufacturing sector. The National Bureau of Statistics of China reported that the manufacturing sector accounted for approximately 27% of the gross domestic product (GDP) in 2021, with further growth anticipated. This robust manufacturing environment necessitates increased investment in precision tools, including tool holders, to enhance productivity and efficiency.Moreover, the Chinese government's initiative to foster high-end manufacturing and innovation will further amplify the demand for sophisticated tool holders. With prominent enterprises like Huawei and Tencent leading technological advancements, there is an inherent demand for tools that ensure accuracy in the production process, thereby supporting tool holder market development. This shift towards automation and advanced manufacturing processes indicates a long-term upward trajectory within the tool holder industry in China.

Investment in Infrastructure Development

China's ongoing investment in infrastructure development significantly contributes to the growth of the China Tool Holder Market Industry. The Ministry of Housing and Urban-Rural Development of China announced plans to invest over USD 1 trillion in transportation infrastructure by 2030, including roads, bridges, and railways. This extensive infrastructure project necessitates the use of advanced manufacturing technologies, including precise tool holders, to ensure efficient construction practices.With the growth of infrastructure projects, construction and civil engineering businesses are likely to require high-quality tool holders to cope with increased speed and precision. Their changing needs are likely to drive market growth. Infrastructure investment, along with policy directions, are positive signs for upcoming years in tool holder industry.

Emergence of Smart Manufacturing

The advent of smart manufacturing technologies in China drives a radical transformation in the tool holder market. The China Ministry of Industry and Information Technology highlighted the significant push towards integrating Internet of Things (IoT) technologies in industrial operations, with projections that smart manufacturing will contribute over 30% to the national manufacturing sector by 2025. This transformation necessitates precision and intelligent tool holders that can function seamlessly with automated systems.Leading companies such as Siemens and General Electric are investing heavily in smart manufacturing practices, which require advanced tool holders to ensure precision tooling. This ongoing shift not only increases the demand for innovative tool holders but also promotes a tech-savvy culture within the industry, contributing to a stronger market landscape.

China Tool Holder Market Segment Insights:

Tool Holder Market Tool Holder Insights

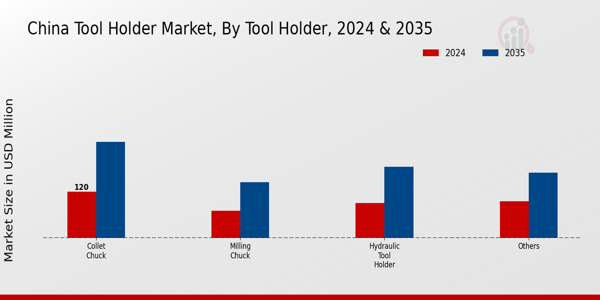

The Tool Holder segment within the China Tool Holder Market is experiencing notable growth driven by the nation's continuous advancement in manufacturing and processing technologies. As China's industrial sector further modernizes, the demand for precision and efficiency in machining operations has increased, highlighting the crucial role of tool holders. Among the various types of tool holders, the Collet Chuck stands out for its ability to provide high clamping force and precise tooling, making it indispensable for tasks that require tight tolerances.Similarly, the Hydraulic Tool Holder has gained popularity due to its ability to absorb vibrations and improve tool life, thus enhancing overall operational efficiency. The Milling Chuck segment represents another significant area, catering to the diverse needs of machining operations by offering flexibility and adaptability for different milling applications. Additionally, the Others category encompasses various innovative tool holder designs that cater to specialized applications, reflecting the diversity in the market. Overall, the market's growth is supported by the increasing adoption of advanced manufacturing technologies such as CNC machinery, driving the demand for reliable and efficient holding solutions.In summary, the dynamic landscape of the China Tool Holder Market reveals a focus on innovation and efficiency, positioning tool holders as vital components in the pursuit of high-quality manufacturing outcomes, ultimately contributing to the growth and competitiveness of China's industrial sector.

Source: Primary Research, Secondary Research, MRFR Database and Analyst Review

Tool Holder Market Product Type Insights

The Product Type segment in the China Tool Holder Market reveals a diverse and competitive landscape essential for various industrial applications. The R8 tool holders hold a significant share due to their versatility and ease of use, making them prevalent in machining environments. V-Flange Taper tool holders are gaining traction for their robustness and precision in high-speed applications, driving increased adoption in manufacturing sectors. Meanwhile, NMTB holders are noted for their reliability and are preferred in drilling operations, thus contributing to their steady demand.HSK tool holders are experiencing a surge in usage due to their compact design and superior stability, making them ideal for high-performance machining tasks. Other tool holder types are also present, offering unique features tailored to specialized applications in the expansive Chinese manufacturing sector. The growth of these segments is supported by the increasing automation and modernization within the industry, as well as the rising focus on precision engineering and productivity improvements. As such, the overall dynamics of the China Tool Holder Market segmentation reflect the ongoing evolution in manufacturing techniques and technologies.

Tool Holder Market Machine Type Insights

The Machine Type segment of the China Tool Holder Market showcases a diverse range of applications contributing significantly to the overall market dynamics. CNC Machining Centers are pivotal, as they enable high precision and efficiency in various machining tasks, reflecting the growing trend towards automation in manufacturing. The CNC Turning Centers are equally vital, catering to industries requiring intricate rotational components and enhancing design flexibility. CNC Lathes are fundamental for producing detailed parts, dominating the market owing to their adaptability in various production scenarios.Other machine types continue to gain traction, filling niche market demands and contributing to the market's overall growth. The increasing demand for precision-engineered products across numerous industries, including automotive and aerospace, is driving the evolution and technological advancements in these machines. The focus on enhancing production capabilities while maintaining cost-effectiveness presents numerous opportunities within this segment, benefiting from the expanding manufacturing base in China. As such, the Machine Type segment plays a crucial role in shaping the trajectory of the China Tool Holder Market, aligning with the broader trends of industrial modernization and enhanced productivity.

Tool Holder Market Industry Vertical Insights

The Industry Vertical segment within the China Tool Holder Market showcases a diverse range of applications, reflecting the country's robust industrial landscape. The automotive sector plays a pivotal role in driving demand for tool holders, given the increasing production of vehicles and the emphasis on precision engineering. In the Aviation and Defense segment, stringent quality standards and the need for high-performance tooling solutions bolster the market as the sector seeks advanced manufacturing capabilities. The Electrical and Electronics industry leverages tool holders for the production of intricate components, while the Construction segment benefits from the growing infrastructure development in China, leading to greater utilization of heavy machinery.The Heavy Engineering sector also significantly contributes to the market's dynamics, relying on tool holders for substantial manufacturing processes. Furthermore, other industries, ranging from consumer products to renewable energy, are emerging as potential growth drivers for tool holders in China. Overall, the varied applications across these sectors highlight the critical role of the China Tool Holder Market in enhancing production efficiency and technological advancements.

China Tool Holder Market Key Players and Competitive Insights:

The competitive insights of the China Tool Holder Market reveal a rapidly evolving landscape characterized by innovative products and an increasing demand for precision engineering solutions. With the expanding manufacturing sector in China, which includes automotive, aerospace, and machinery industries, tool holders play a critical role in enhancing productivity and efficiency. Competitors in this market are focusing on technological advancements, which include the development of high-performance materials and design innovations tailored for specific applications. Additionally, the competitive dynamics are influenced by factors such as pricing strategies, supply chain efficiency, and customer service quality. As the market matures, companies are also investing in sustainable practices and solutions, responding to the increasing demand for environmentally friendly manufacturing processes.In terms of strengths within the China Tool Holder Market, EMUGE stands out due to its solid reputation for high-quality and reliable tool holding solutions. The company's products are renowned for their durability and precision, making them essential in high-speed machining applications. EMUGE has established a robust market presence in China, supported by a well-developed distribution network that ensures accessibility to customers across the region. The firm emphasizes research and development, allowing it to consistently launch innovative and technologically advanced tool holders that meet the specific requirements of Chinese manufacturers. EMUGE's commitment to customer satisfaction and after-sales service adds further value, ensuring strong client relationships and repeat business in this competitive environment.Tungaloy, operating in the China Tool Holder Market, is recognized for its comprehensive range of cutting tools and tool holding systems designed for a variety of machining applications. The company's key products include innovative tool holders that enhance chip removal efficiency while maximizing tool performance. Tungaloy's presence in the Chinese market has been significantly bolstered through strategic partnerships and collaborations, enhancing its ability to cater to local manufacturers. Additionally, Tungaloy has made strides in mergers and acquisitions that expand its product offerings and market reach in China. With a strong focus on research and development, the company continuously evolves its product lines to meet emerging industry needs. The integration of advanced manufacturing technologies and a commitment to quality positions Tungaloy favorably against competitors in the competitive landscape of the China Tool Holder Market.

Key Companies in the China Tool Holder Market Include:

EMUGE

Tungaloy

Kyocera

Haimer

Jiangsu Dongguan

Mitsubishi Materials

LMT Tools

Ingersoll Cutting Tools

Seco Tools

OSG

Schunk

SANDVIK

Walter

KSTool

China Tool Holder Market Industry Developments

The China Tool Holder Market has seen significant developments amidst ongoing industrial advancements. In recent months, companies like EMUGE and Tungaloy have released innovative tool holders designed to enhance machining efficiency, particularly in automotive and aerospace sectors where precision is critical. Notably, in November 2023, Schunk launched a new line of modular tool holders aimed at improving flexibility and reducing setup times for manufacturers. Meanwhile, Haimer has been focusing on expanding its product range tailored to meet the growing demand for high-performance tooling solutions, reflecting a broader trend in the market toward innovation and customization. In terms of mergers and acquisitions, Jiangsu Dongguan announced its acquisition of a smaller regional competitor in October 2023, enabling greater market penetration and resource consolidation in a competitive environment. The recent growth in market valuation for companies like Mitsubishi Materials and SANDVIK indicates a robust demand for cutting solutions, further propelled by China's manufacturing sector's recovery post-pandemic. The increased focus on automation and advanced technology integration continues to deepen competitive dynamics in the tool holder segment, aligning with China's broader economic goals to enhance industrial output and innovation.

China Tool Holder Market Segmentation Insights

Tool Holder Market Tool Holder Outlook

Collet Chuck

Hydraulic Tool Holder

Milling Chuck

Others

Tool Holder Market Product Type Outlook

R8

V-Flange Taper

NMTB

HSK

Others

Tool Holder Market Machine Type Outlook

CNC Machining Center

CNC Turning Center

CNC Lathe

Others

Tool Holder Market Industry Vertical Outlook

Automotive

Aviation & Defense

Electrical & Electronics

Construction

Heavy Engineering

Others

Market Size & Forecast

| Report Attribute/Metric Source: | Details |

| MARKET SIZE 2018 | 315.0(USD Million) |

| MARKET SIZE 2024 | 375.0(USD Million) |

| MARKET SIZE 2035 | 749.0(USD Million) |

| COMPOUND ANNUAL GROWTH RATE (CAGR) | 6.491% (2025 - 2035) |

| REPORT COVERAGE | Revenue Forecast, Competitive Landscape, Growth Factors, and Trends |

| BASE YEAR | 2024 |

| MARKET FORECAST PERIOD | 2025 - 2035 |

| HISTORICAL DATA | 2019 - 2024 |

| MARKET FORECAST UNITS | USD Million |

| KEY COMPANIES PROFILED | EMUGE, Tungaloy, Kyocera, Haimer, Jiangsu Dongguan, Mitsubishi Materials, LMT Tools, Ingersoll Cutting Tools, Seco Tools, OSG, Schunk, SANDVIK, Walter, KSTool |

| SEGMENTS COVERED | Tool Holder, Product Type, Machine Type, Industry Vertical |

| KEY MARKET OPPORTUNITIES | Growing demand for automation, Expansion in manufacturing sector, Increasing investments in R&D, Rising adoption of advanced materials, Focus on precision engineering |

| KEY MARKET DYNAMICS | growing manufacturing sector, increasing automation trends, demand for precision tools, focus on cost efficiency, technological advancements in materials |

| COUNTRIES COVERED | China |

Major Players

China Tool Holder Market Segmentation

-

Tool Holder Market By Tool Holder (USD Million, 2019-2035)

-

Collet Chuck

-

Hydraulic Tool Holder

-

Milling Chuck

-

Others

-

-

Tool Holder Market By Product Type (USD Million, 2019-2035)

-

R8

-

V-Flange Taper

-

NMTB

-

HSK

-

Others

-

-

Tool Holder Market By Machine Type (USD Million, 2019-2035)

-

CNC Machining Center

-

CNC Turning Center

-

CNC Lathe

-

Others

-

-

Tool Holder Market By Industry Vertical (USD Million, 2019-2035)

-

Automotive

-

Aviation & Defense

-

Electrical & Electronics

-

Construction

-

Heavy Engineering

-

Others

-

Leave a Comment