Market Summary

Germany Tool Holder Market Overview:

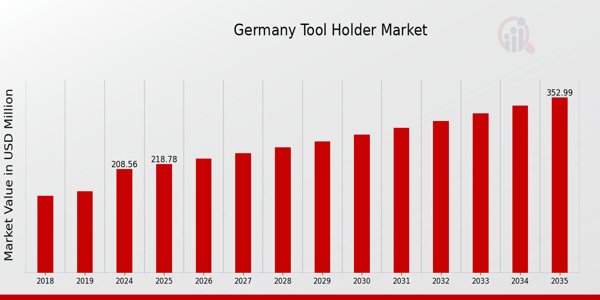

As per MRFR analysis, the Germany Tool Holder Market Size was estimated at 198 (USD Million) in 2024.The Germany Tool Holder Market Industry is expected to grow from 208.56(USD Million) in 2025 to 353 (USD Million) by 2035. The Germany Tool Holder Market CAGR (growth rate) is expected to be around 4.9% during the forecast period (2025 - 2035).

Key Germany Tool Holder Market Trends Highlighted

The Germany Tool Holder Market has shown significant trends that are shaping its future. One key market driver is the increasing demand for precision engineering and advanced manufacturing technologies. German industries, particularly in automotive and aerospace sectors, prioritize accuracy and efficiency, leading to a surge in the adoption of sophisticated tool holders designed to optimize machining operations. Additionally, the strong focus on automation and Industry 4.0 initiatives in Germany has encouraged manufacturers to invest in advanced tooling solutions that enhance productivity and reduce operational downtime. The integration of smart technologies into tool holders is a notable trend, providing real-time data and analytics to improve performance and maintenance planning.Opportunities to be explored in the German market include the rising trend of sustainable manufacturing practices. As companies seek to reduce their environmental impact, there is an increasing demand for eco-friendly materials and energy-efficient tool holders. This shift opens doors for innovation in design and production methods, catering to the growing base of environmentally conscious manufacturers in Germany. Another opportunity arises from the expansion of the small and medium-sized enterprises (SMEs) sector, which is a vital part of the German economy. These enterprises are increasingly seeking affordable yet effective tooling solutions, creating a niche for manufacturers who can provide tailored products.Recent times have seen a shift toward custom-made solutions to address specific industry requirements. With advancements in additive manufacturing and the customization capabilities that come with it, suppliers are now more able to deliver tool holders that fit unique specifications for various applications. Furthermore, the ongoing emphasis on workforce skill development in Germany is expected to drive the need for training programs that ensure optimal use and maintenance of advanced tool holder systems, which enhances overall productivity in workshops and manufacturing units across the region.

Source: Primary Research, Secondary Research, MRFR Database and Analyst Review

Germany Tool Holder Market Drivers

Increasing Automation and Industry 4.0 Adoption

Germany is at the forefront of adopting automation technologies and Industry 4.0 principles within its manufacturing sector. This shift necessitates precise tooling systems that are integral to modern manufacturing processes, leading to a higher demand for advanced tool holders. According to the German Federal Ministry for Economic Affairs, investments in digital technologies have increased by 20% over the past five years, signaling a significant push towards automation.Siemens and Bosch are among those leading this change, urging other producers to improve their equipment and tooling skills, which intensifies the need for the Germany Tool Holder Market Industry. Because automation is already growing, the incorporation of intelligent tool holders will most probably become a benchmark, ensuring continuous development in this market.

Growing Demand for High-Precision Machining

High-precision machining is crucial in industries such as aerospace, automotive, and medical devices, sectors that are robust in Germany. The need for high-quality finishes and tight tolerances has led to an increased focus on tool holders that can deliver precise performance. Statistics from the German Statistical Office indicate that the precision engineering sector grew by 8% in the last year alone. Major players like DMG Mori and Trumpf are setting the standards in high-precision manufacturing, driving up the need for specialized tool holders.This rising demand for accuracy in machining processes significantly boosts the Germany Tool Holder Market Industry, making it a vital component of modern manufacturing.

Sustainability Initiatives in Manufacturing

Sustainability is becoming more important in Germany's manufacturing sector, influencing the tools and technologies adopted by companies. The German government has implemented policies to reduce carbon emissions, leading manufacturers to invest in more sustainable and efficient production methods, which include upgrading their tooling systems. A report from the German Ministry for the Environment reveals that industries are aiming for a 55% reduction in greenhouse gases by 2030 compared to 1990 levels.Companies like Volkswagen and BMW have initiated programs to lower their environmental impact, prompting the shift towards sustainable tooling solutions, thereby increasing the demand for innovative tool holders within the Germany Tool Holder Market Industry.

Germany Tool Holder Market Segment Insights:

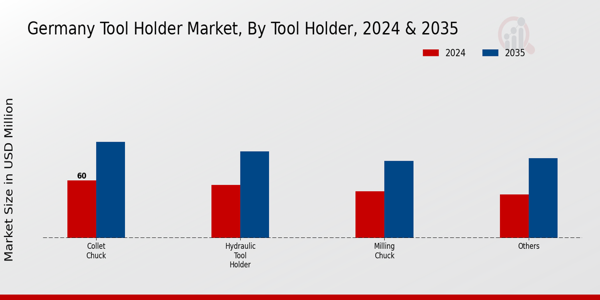

Tool Holder Market Tool Holder Insights

The Germany Tool Holder Market is experiencing steady growth and is characterized by a diverse range of product types that cater to various industrial applications. Among these, Collet Chucks are prominent for their versatility and precision, making them favored choices in CNC machining and woodworking applications. They hold the workpiece securely and provide excellent clamping force, allowing for high-accuracy manufacturing processes. Hydraulic Tool Holders are also significant within this market segment, offering advantages in terms of damping and vibration reduction, which enhances tool life and improves surface finish in machining operations.Additionally, Milling Chucks are crucial as they enable high-torque transmission and are designed to accommodate larger cutting tools, which enhances efficiency and performance in milling processes. The Others category encapsulates a variety of tool holders designed for specific applications, including modular components and custom solutions that address niche requirements across different industries. This segmentation reflects the growing trend of customization in manufacturing and the need for adaptable tool holding solutions that can meet specific operational challenges.The demand for high-quality tool holders in Germany is driven by the country’s robust engineering sector and its strong focus on precision manufacturing. Challenges such as the need for sustainability and innovation also present opportunities for market growth as companies look to develop eco-friendly materials and technologies. Overall, the Germany Tool Holder Market segmentation showcases a dynamic landscape influenced by technological advancements and evolving industry needs.

Source: Primary Research, Secondary Research, MRFR Database and Analyst Review

Tool Holder Market Product Type Insights

The Germany Tool Holder Market showcases a dynamic landscape with various product types catering to a diverse industrial need, vital for sectors such as automotive, aerospace, and manufacturing. The Product Type segment includes categories such as R8, V-Flange Taper, NMTB, HSK, and others, each playing a crucial role in precision machining. The R8 type is widely recognized for its adaptability and ease of use, making it a preferred choice in many workshops. V-Flange Taper holders are significant for their stability and compatibility with high-speed applications, bridging performance and efficiency.NMTB types offer robust performance for heavy-duty machining tasks, while HSK tool holders are known for their innovative design that enhances tool stability and precision during operation. The Others category encapsulates various innovative solutions, addressing specific industrial challenges. Collectively, these product types contribute to the growth and competitive edge of the Germany Tool Holder Market, responding to the evolving demands for improved accuracy, efficiency, and productivity in manufacturing processes. The significance of these segments is further underscored by Germany's strong manufacturing sector, which prioritizes high-quality tooling solutions to maintain its competitive position in the global market.

Tool Holder Market Machine Type Insights

The Germany Tool Holder Market, particularly under the Machine Type segment, exhibits significant segmentation including CNC Machining Center, CNC Turning Center, CNC Lathe, and others, each playing a crucial role in the industry's dynamics. CNC Machining Centers are essential due to their capabilities in performing multiple machining operations, making them highly efficient and versatile in manufacturing processes. In contrast, CNC Turning Centers provide precision and automation predominantly for the production of symmetrical parts, which is a vital need in automotive and aerospace sectors in Germany, known for their robust manufacturing foundations.CNC Lathes offer specialized performance for creating cylindrical shapes, addressing the specific demands of industry applications. The other category encapsulates various innovative tool holders adapting to niche requirements. Overall, each of these segments contributes distinctly to the market's evolution, driven by technological advancements and increased automation in manufacturing processes. Moreover, the growing focus on smart manufacturing solutions in Germany aligns with the demand for sophisticated tools that enhance productivity and operational efficiency, creating a vibrant landscape for the Tool Holder Market.The industry’s growth is also supported by a skilled workforce and Germany's strong engineering tradition, fostering collaborations and innovations within these machine types.

Tool Holder Market Industry Vertical Insights

The Germany Tool Holder Market showcases a diverse range of industry verticals, each contributing significantly to the overall dynamics of the market. The automotive sector is vital, as Germany is known for its robust automotive manufacturing, which drives the demand for precision tool holders. Similarly, the aviation and defense industries rely heavily on specialized tool holders for their stringent quality and safety standards, thus underscoring their importance in this market. The electrical and electronics segment also plays a crucial role as modern technology demands high-precision tools for manufacturing, leading to continuously evolving designs.In construction, the need for durable tool holders is critical for effectively managing heavy workloads and ensuring operational safety. Heavy engineering further necessitates strong tool holders that can handle intense mechanical stresses and variations in conditions. Other sectors round out the industry's diversity, with utility in a variety of applications offering unique opportunities for growth. This segmentation of the Germany Tool Holder Market highlights not only the different demands each sector presents but also the necessity for innovation to meet these varied needs, reflecting overall market trends toward specialization and customization in tool holder solutions.

Germany Tool Holder Market Key Players and Competitive Insights:

The competitive landscape of the Germany Tool Holder Market is characterized by a mix of established players and emerging companies vying for market share. This dynamic environment is marked by rapid technological advancements, increasing demand for precision tools, and a focus on enhancing manufacturing efficiency. The market is influenced by factors such as industrial automation trends, stringent quality standards, and the growing need for cost-effective tooling solutions among manufacturers. Overall, the competitive insights reveal a strong emphasis on innovation, customization, and service quality as key drivers for success in this market.Koma has carved out a significant presence in the Germany Tool Holder Market by leveraging its deep expertise in tool holder technology and innovative design. The company is renowned for its high-quality products that boast exceptional precision, durability, and reliability, catering specifically to the needs of the automotive and aerospace sectors. Koma's strength lies in its ability to offer a diverse range of tool holders that are compatible with various machine tools, making it a preferred choice for manufacturers seeking versatility. Furthermore, Koma has established strong relationships with key players in the industry, enhancing its market presence and reputation for excellence. The company's commitment to customer satisfaction and after-sales support further solidifies its standing in a competitive landscape.Tungaloy, another prominent player in the Germany Tool Holder Market, has positioned itself as a leader by providing innovative solutions that enhance machining efficiency and productivity. Known for its high-performance cutting tools and tool holders, Tungaloy focuses on delivering advanced materials and designs that cater to specific manufacturing applications. The company's strengths include a broad portfolio of products, encompassing turning, milling, and hole-making tools, which offer a comprehensive solution for various industrial needs. Tungaloy has made strategic moves through mergers and acquisitions to strengthen its market foothold, resulting in expanded capabilities and improved product offerings tailored the German market. The company's dedication to research and development ensures that it remains at the forefront of tool holder technology, allowing it to effectively meet the demands of its customer base in Germany.

Key Companies in the Germany Tool Holder Market Include:

Koma

Tungaloy

WNT

Haimer

Flexibility

Kennametal

MAPAL

Walter Tools

Sandvik Coromant

Mitsubishi Materials

Seco Tools

Iscar

Schunk

Walter

Germany Tool Holder Market Industry Developments

In recent months, the Germany Tool Holder Market has seen dynamic developments, reflecting a growing demand driven by advancements in manufacturing technologies. Companies such as Koma, Tungaloy, WNT, and Haimer have reported increases in market valuation attributed to innovations in tool holder designs that enhance precision and efficiency. Moreover, in September 2023, Kennametal announced the acquisition of a technology-focused firm that aimed to expand its digital manufacturing capabilities within Germany. Meanwhile, MAPAL and Walter Tools have collaborated on a project aimed at improving the eco-friendliness of tool holders through sustainable materials. Germany's industrial production surged by over 5% in Q2 2023, beneficially impacting tool holder demands and reflecting robust manufacturing activity. Additionally, the transition towards Industry 4.0 has driven the integration of smart technologies among key players including Sandvik Coromant and Mitsubishi Materials, leading to customized solutions for end-users. Over the past two years, the market has been responding to the evolving needs of various sectors, marking a significant evolution in Germany's tool holder landscape amid shifting economic and technological paradigms.

Germany Tool Holder Market Segmentation Insights

Tool Holder Market Tool Holder Outlook

Collet Chuck

Hydraulic Tool Holder

Milling Chuck

Others

Tool Holder Market Product Type Outlook

R8

V-Flange Taper

NMTB

HSK

Others

Tool Holder Market Machine Type Outlook

CNC Machining Center

CNC Turning Center

CNC Lathe

Others

Tool Holder Market Industry Vertical Outlook

Automotive

Aviation & Defense

Electrical & Electronics

Construction

Heavy Engineering

Others

Market Size & Forecast

| Report Attribute/Metric Source: | Details |

| MARKET SIZE 2018 | 198.0(USD Million) |

| MARKET SIZE 2024 | 208.56(USD Million) |

| MARKET SIZE 2035 | 353.0(USD Million) |

| COMPOUND ANNUAL GROWTH RATE (CAGR) | 4.9% (2025 - 2035) |

| REPORT COVERAGE | Revenue Forecast, Competitive Landscape, Growth Factors, and Trends |

| BASE YEAR | 2024 |

| MARKET FORECAST PERIOD | 2025 - 2035 |

| HISTORICAL DATA | 2019 - 2024 |

| MARKET FORECAST UNITS | USD Million |

| KEY COMPANIES PROFILED | Koma, Tungaloy, WNT, Haimer, Flexibility, Kennametal, MAPAL, Walter Tools, Sandvik Coromant, Mitsubishi Materials, Seco Tools, Iscar, Schunk, Walter |

| SEGMENTS COVERED | Tool Holder, Product Type, Machine Type, Industry Vertical |

| KEY MARKET OPPORTUNITIES | Increased automation demand, Growth in manufacturing sector, Expansion of aerospace industry, Rising preference for precision tools, Sustainable and eco-friendly materials |

| KEY MARKET DYNAMICS | technological advancements, increasing automation, demand for precision tools, growth of manufacturing sector, focus on sustainability |

| COUNTRIES COVERED | Germany |

Major Players

Germany Tool Holder Market Segmentation

-

Tool Holder Market By Tool Holder (USD Million, 2019-2035)

-

Collet Chuck

-

Hydraulic Tool Holder

-

Milling Chuck

-

Others

-

-

Tool Holder Market By Product Type (USD Million, 2019-2035)

-

R8

-

V-Flange Taper

-

NMTB

-

HSK

-

Others

-

-

Tool Holder Market By Machine Type (USD Million, 2019-2035)

-

CNC Machining Center

-

CNC Turning Center

-

CNC Lathe

-

Others

-

-

Tool Holder Market By Industry Vertical (USD Million, 2019-2035)

-

Automotive

-

Aviation & Defense

-

Electrical & Electronics

-

Construction

-

Heavy Engineering

-

Others

-

Leave a Comment